Punching and drawing technology

With over 100 years of experience

we shape materials to perfection

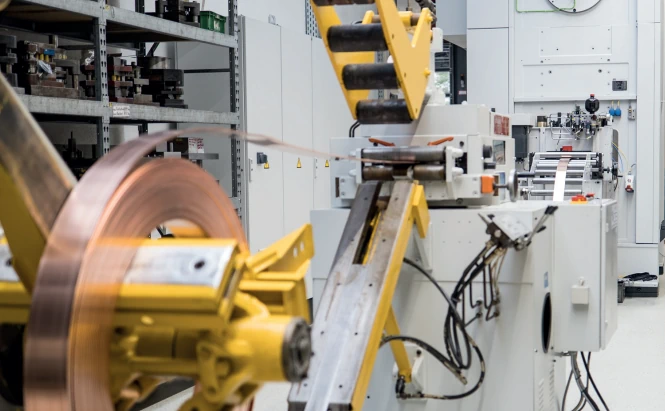

Your stamped and drawn parts are in expert hands with Becker Metalltechnik – synonymous with maximum precision in metal processing. State-of-the-art system technology guarantees consistently consistent results, and you benefit from high dimensional accuracy and minimised tolerances. We process all common metals and provide surface finishes precisely to your specifications. We keep a constant focus on quality, cost-effectiveness and on-time delivery.

Our core competencies

I PUNCHING I BENDING I DRAWING I THREADING I DRILLING I

I COUNTERSINKING I RIVETING I PRESSING I SPOT WELDING I

Small batches

large-scale series

Take advantage of our flexible machinery setup – ideal for prototypes, small batches or high-volume production. Our manufacturing processes are certified to DIN EN ISO 9001:2015.

Would you like to learn more or request a no-obligation quote?

A dedicated contact person will support you from your first enquiry to the finished product.

Powering your project -

from raw material to

finished component

Mechanical 1600 kN

Hydraulic 1000 kN

1600 x 1000 mm

Materials: All common metals and desired surfaces

Punching machine list

Warehouse logistics

part of our process chain

End-to-end processes – precisely coordinated from start to finish. At Becker, we see logistics and production not as separate steps but as a tightly integrated whole. From raw-material storage to precise manufacturing, efficient post-processing and on-schedule delivery – every step is systematically organised and digitally coordinated. Every step is systematically organised and technologically coordinated.

This ensures your production is always supplied reliably; with the right parts, in the right quantity and quality, at the right time.

Our process structure offers:

- High supply reliability through controlled material flows

- Efficient workflows through digitally supported production control

- Consistent quality through coordinated processing stages

- Reliable delivery performance through transparent

and automated logistics planning